At Framery, we are continuously striving to make our operational footprint smaller and our handprint bigger, to ensure that we are not just creating happiness today, but also sustainable happiness for future generations. We have set up clear, transparent, and long-standing goals for environmental efficiency, including material efficiency, circular economy, and minimizing energy and greenhouse gas emissions.

As a manufacturing company, logistics are a big part of our everyday operations. And as everyday actions matter the most when minimizing the carbon footprint, we started near and teamed up with Kaukokiito to reduce our local logistics climate impacts. By changing from fossil fuel to biogas we succeeded together with a reduction of 90%! Let’s take a deeper look at how we did it and why.

Reducing our carbon footprint

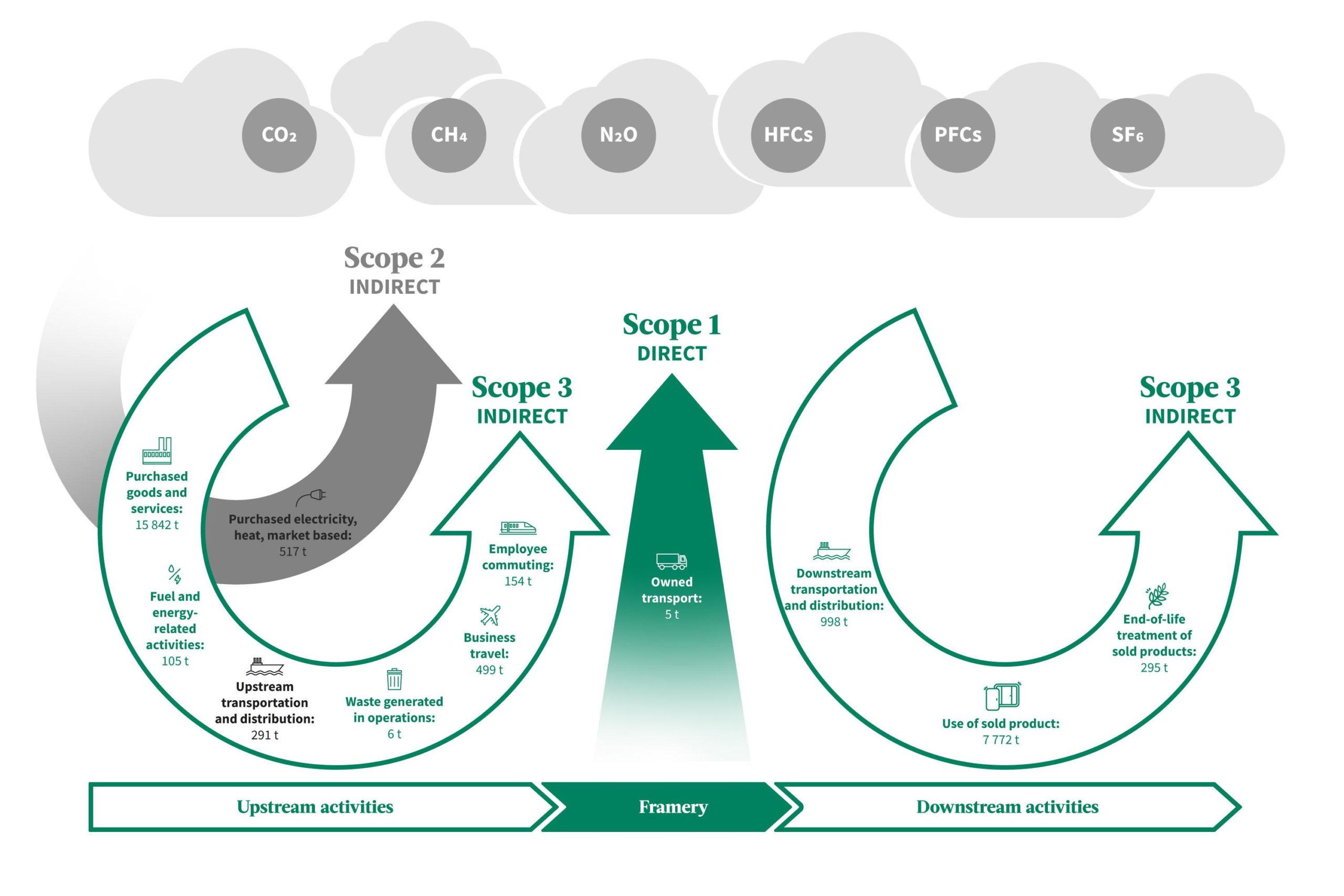

With a commitment to reduce our carbon footprint year-to-year, we joined the Science Based Targets initiative in 2020. Through this initiative, we have pledged to meet emission reduction goals outlined in the historic Paris Agreement. The agreement limits global warming to well below 2°C above pre-industrial levels and pursues efforts to limit warming to 1.5°C. To meet this goal, we are reducing our absolute scope 1 and scope 2 greenhouse gas (GHG) emissions by 50% by 2030 from a 2018 base year, and to measure and reduce our scope 3 emissions.

But what does all of this look like in practice? We understand that these big goals cannot be accomplished alone. We have partnered with Kaukokiito to outsource our dispatch and storage operations in Finland. Kaukokiito operates the logistics from our suppliers to the Kaukokiito warehouse and the milk run from the warehouse to our factory and back. The milk runs share in our scope 3 upstream transportation and distribution is 13,5 t. Kaukokiito and Framery both are committed to minimizing operational carbon footprint. After discussing concrete changes Framery could make to reach this goal, Kaukokiito suggested the introduction of a biogas truck to operate the daily factory-warehouse-factory route.

90% of emissions will be cut.

Biogas is produced from waste feedstocks such as biowaste, sewage sludge, manure, and other industrial and agricultural side streams. Nutrient residues from biogas production are then utilized as fertilizers in fields. Using recycled fertilizers reduces the need to use conventional artificial fertilizers. This fully renewable and circular fuel can help to reduce life-cycle greenhouse gas emissions by up to 90% compared to fossil fuel use. With this kind of cooperation beyond company borders, we can accomplish great results towards a more sustainable and better environment. “Responsibility and environmental issues are important to us, and we will invest even more in related activities and communication in the future,” says Timo Maijala, Kaukokiito’s Sales Director. “We also want to challenge our customers and partners to the responsibility debate and the concrete actions derived from it. A successful example of this is the Framery collaboration.”

Our greenhouse gas emissions

In 2019, Framery began making screening calculations on its different scopes of GHG emissions. During 2020, we further enhanced our understanding, as well as analytical data gathering, of the impact of different parts of our overall operations on our emissions. Scope 3 emissions are defined as all indirect emissions that are the result of activities from assets or utilities not owned or controlled by Framery, but on which Framery indirectly impacts in its value chain. In 2020, a total of 291 tonnes of CO2 were produced from transportation emissions from suppliers to the warehouse and the milk run from the warehouse to our factory and back.

Using biogas-run trucks for the milk run, 90% of emissions will be cut and the complete scope 3 upstream transportation and distribution will decrease by about five percent. “The world needs real concrete actions and collaborations like this to reduce GHG emissions,” says Kirsti Sääjärvi, Framery’s Sustainability Lead. “Even the smallest efforts are important, everything counts. We want to be showing an example and taking leadership in implementing initiatives like this.” Framery is also proud to say that the entire office and production facilities run on 100% renewable electricity. In addition, Framery is renting 60 solar panels from a Finnish solar plant to support local renewables production.

Our entire office and production facilities run on 100% renewable electricity.

Framery is the pioneer and the world’s leading manufacturer of pods, phone booths, and soundproof private spaces and we understand the importance this holds in making a difference in corporate responsibility. By continuing to invest in innovations like biogas trucks and renewable energy sources, we are showing other world leaders that company goals can be achieved sustainably.

Explore our whole sustainability report here!